Fire Pumps, The Heart Of Your Fire Protection System!

The NFPA 20, Chapter 4 contains general requirements for fire pumps. It is important to note that NFPA 20 does not establish the requirement to install a fire pump.

The need for fire pumps is based on the hydraulic demand of suppression systems and the flow and pressure provided by available water supply, as outlined in the NFPA System Design for Fire Sprinkler & or Standpipe Systems.

Where a fire pump(s) is part of the fire protection system, the design, installation, and acceptance testing requirements should be in accordance with this standard.

Services

Chapter 8 of the State adopted NFPA 25 contains the minimum requirements for the routine inspection, testing, and maintenance of fire pump assemblies, which are vital for a healthy Fire Pump.

-

Diesel engine–driven fire pumps shall be operated weekly.

-

Electric motor–driven fire pumps shall be operated monthly.

- Weekly, Monthly, Annually

- Inspections

- Testing

- Maintenance

*All work is performed per the NFPA 20, State adopted NFPA 25 and the Local Authority Having Jurisdiction.

When pumps that were put in place to protect a facility must be removed from service for repairs, the facility can become unprotected for the duration of the repair.

Thus, the failure to properly maintain fire pumps and related equipment can quickly result in significant direct and indirect costs.

Repairs

A lack of Service can cause greater issues for your Fire Pump.

Chapter 8 of the State adopted NFPA 25 gives incite on “next steps” after any change has taken place with your Fire Pump.

8.6 Component Replacement Testing Requirements.

8.6.1 Whenever a component in a fire pump is adjusted, repaired,

rebuilt, or replaced, the tests required to restore the system to service

shall be performed in accordance with Table 8.6.1.

In some of these situations, the protection of property and life is considered impaired, resulting in a shutdown of operations mandated by the authority having jurisdiction (AHJ) until repairs are made.

This shutdown could result in major business interruption loss and costly pump repairs.

Bolt Mechanical, Inc. is there for you!

- Entire Pump Assembly (Wet End)

- Complete Controller Replacements

- Electric/Diesel Motor Assembly (Dry End)

- Drive Coupling

- Jockey Pumps

- Bypass Loops and Meter

- System Valves

- ** Acceptance Test

*All work is performed per the NFPA 20, State adopted NFPA 25 and the Local Authority Having Jurisdiction.

** It is not necessary in each case to require a complete acceptance test for each component when maintenance is performed.

New Installations

NFPA 20, Standard for the Installation of Stationary

Pumps for Fire Protection, shall be consulted for the

minimum requirements for design and installation,

including acceptance testing and component replacement.

- New Projects

- Expansions

- Upgrades

- Tenant Improvements

- Plan Design & Submittal

*Work performed per the NFPA 13 & 20 and the Local Authority Having Jurisdiction.

Click here to learn more about our other services.

Document Control

Bolt Mechanical provides you with the required State Fire Marshal Certificates for your Fire and Life Safety systems.

If your Authority Having Jurisdiction (AHJ) contracts with The Compliance Engine, we send the required reports to them via our account.

Are you in a Los Angeles City Fire Chiefs Regulation 4 area? We submit those documents for you as well!

Access to your files on our cloud server at anytime, anywhere will keep your records straight and up-to-date whenever you need them.

Call Anytime!

Learn more about document Control

Fire Pumps Tech Tips

Do I Need A Fire Pump?

FAQ-NFPA

When is a fire pump needed?

The need for a fire pump is usually determined through an analysis of the fire protection system being considered, the liquid supply required for the system, and the liquid supply available. Fire pumps are principally used where pressure from the attached liquid supply is insufficient (pumps used for this purpose are sometimes referred to as booster pumps). Where capacity of the water supply is also in question, means in addition to a fire pump, such as water tanks, also need to be considered.

When considering whether a fire pump is necessary, the user should refer to the other NFPA standards that address various types of water-based fire protection systems.

You’ve determined that you do need a fire pump.

The NFPA 20, Standard for the Installation of Stationary

Pumps for Fire Protection, shall be consulted for the

minimum requirements for design and installation,

including acceptance testing and component replacement.

4.16.6* Installation.

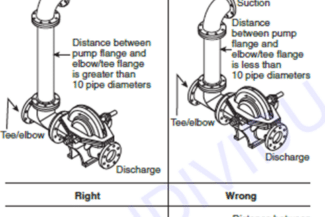

Avoid common mistakes.

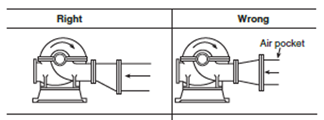

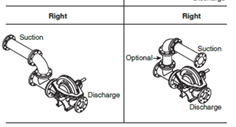

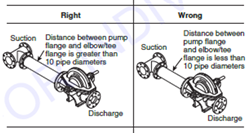

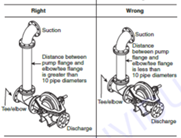

4.16.6.1 General. Suction pipe shall be laid carefully to avoid

air leaks and air pockets, either of which can seriously affect

the operation of the pump.

4.16.6.4 Eccentric Tapered Reducer or Increaser. Where the

suction pipe and pump suction flange are not of the same size,

they shall be connected with an eccentric tapered reducer or

increaser installed in such a way as to avoid air pockets.

See NFPA 20 figure (s) A.4.16.6 Right and Wrong Pump Suctions